Your Cart is Empty

September 27, 2021 4 min read

Why do we produce 3.5" molds first?

Because the production process of 3.5" blank RabbotZ is completely different with 6" and 12" blank RabbotZ, steel molds are required for mass production. While the production time of steel molds is quite long which usually takes more than 45 days. What’s more, the order number of 3.5" RabbotZ on Kickstarter is the largest.

Therefore, in order to ensure delivery and make our backers receive their RabbotZ at Christmas, the production of steel molds needs to be started first.

From August 6 to September 26, after nearly 2 months’ communication and patient waiting, the 3.5" RabbotZ mold was finally completed.

Here is the process:

START THE PRODUCTION OF MOLDS FIRST

Two weeks before the launch of our Kickstarter, we have already entered the mold production process. In fact, it started on August 6. Our factory took 2 days to complete the disassembly of 3D mode first, and then entered the formal mold production process.

After a lot of supervision and control during mold production period, the first version of the mold was made on August 25, and we called him T0 Sample. (We will introduce the complex process before the T0 Sample if we have another chance later. More than 10 work procedures, so complicated ah)

This is the mold of T0 Sample

This is T0 RabbotZ produced by T0 Sample mold

Note: The red circle parts of T0 blank RabbotZ are very rough and need to be refined, but the actual parts need to be refined are many times more than those marked in the picture!

This version is very original and rough in many parts.

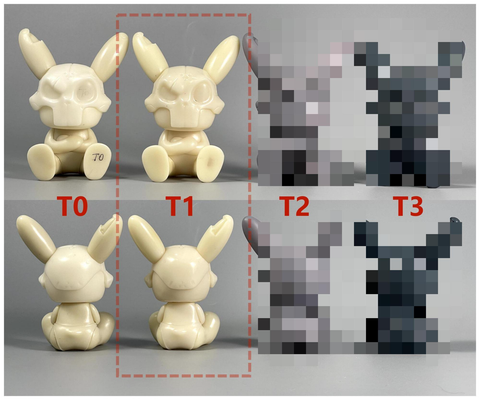

Here is a comparison picture of 3.5" blank RabbotZ produced by T0 and T1, and you can see that the surface of T0 mold is very rough, and has not been polished.

Note: The part marked 1 in above picture clearly shows that the mold of T0 is very rough. After refined, the "skin" is very smooth in T1 Sample!

According to the general rules of mold adjustment, it always needs to go through more than three times of adjustments(that is, at least T0 to the T3 Sample) before it is possible to reach the standard of fine products.

The more adjustments made, the higher the cost. The adjustment process is all manual and totally relies on the experience of the master workers. We all know that the labor costs are the highest. :(

The cost of the mold we made is nearly 50% higher than that of the general equivalent mold.

There are two reasons:

One reason is that we require absolute fine quality of products, which leads to an increase in labor costs.

The other reason is that we require to speed up the production of blank RabbotZ, so we add one more set of molds, leading to a lot of cost increased.

START TO REFINE THE MOLD

1. This is the 3.5" blank RabbotZ in the T1 Sample after the first mold refinement.

Main adjustments from T0 to T1:

Mainly adjusting the chinks of connections parts of hand, thigh and body, so that the body will nearly has no chinks; Other polish and minor adjustments are countless and numerous.

2. This is the 3.5 blank RabbotZ in the T2 Sample after the second mold refinement.

Main adjustments from T1 to T2:

The smoothness of the scar edge of the right eye;

The chink under the RabbotZ teeth;

The depth of the lower eyelid of RabbotZ eye adjusts to be more shallow;

Refined all Spue Lines of the mold.

3. This is the 3.5 blank RabbotZ in the T3 Sample after the third mold refinement

Main adjustments from T2 to T3:

Refined the connection between the mouth's lower edge of the helmet and the face;

Refined all parts of the body that need to be bonded;

Refined all parts again with obvious Spue Lines.

This period we did many magnetic tests. At first we wanted to use iron sheets at one end and magnets at the other end. And increasing and thickening the iron sheets to strengthen the strength of the magnets. It can minimize assembly errors.

However, it was found that the magnetic effect did not meet our requirement, so we asked the factory to install magnets on both sides. Of course, the cost was nearly doubled compared with using one side magnet.

Generally, the T3 Sample mold was enough for most products, but we found that there are still minor defects in some tiny parts, which will lead to imperfections in final colored products. So given time permits, we asked the factory to refine the mold again. (the factory is actually very unwilling.)

4. This is the 3.5" blank RabbotZ of the final T4 Sample.

After the confirmation of the mold of T4 Sample, the production of the mold of mass production will begin.

This part is very critical. Due to the complexity of our product coating is 2-3 times than that of general products, (for example, general products need 30 work procedures to produce coating, while we need 60-100 work procedures to produce. Each more work procedure is a test for time and cost!) this part will also cost a lot of time.

Mass production will be carried out according to this standard, and we will make strict control of the quality of this production process. So stay tuned for RabbotZ!